Description

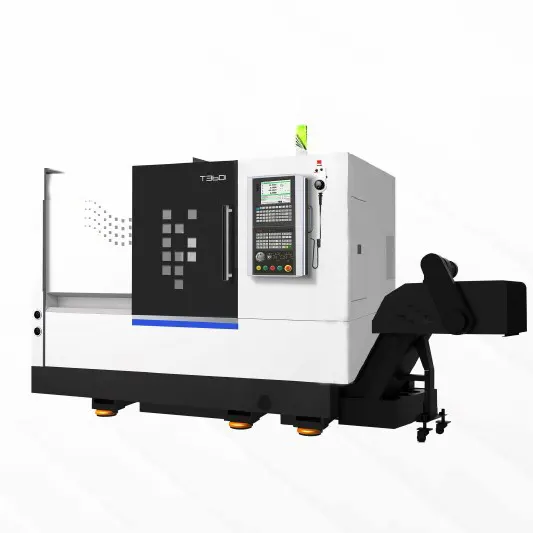

T Series Horizontal CNC Machine Tools

Viva Turn 2 horizontal CNC lathe is a brand new design based on the progressive technology research and development ideas, as also combining with the years of our experience in designing horizontal CNC lathes, borned to better satisfy users.

The main performance indexes of this product have reached the international advanced level. The product has super high precision and stability, also high rigidity structure of large cutting feed, so as to provide the customers high efficiency, high stability, sterling world-class machine costeffectively.

Modularized developing ideas and integrated design concept build platform-oriented machine. The type of components cut down by forty percent. So that the stability increases and further maintenance easily. Comparing with the same kind of machine tools, Viva Turn 2 obtains larger inner space by its smaller shape so that it can machine larger components.

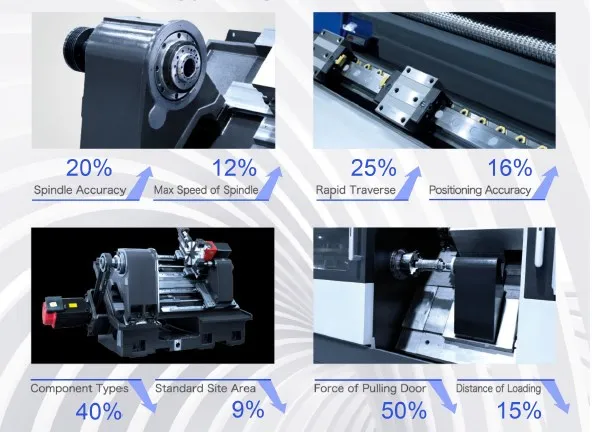

Technology Upgrades:

Application Scope:

VIVA TURN 2/4 has extremely high precision, rigidity, and high stability. High accuracy, efficiency, and flexible and diversified configurations make VIVA TURN 2/4 suitable for all kinds of materials in any field.

Product Introduction:

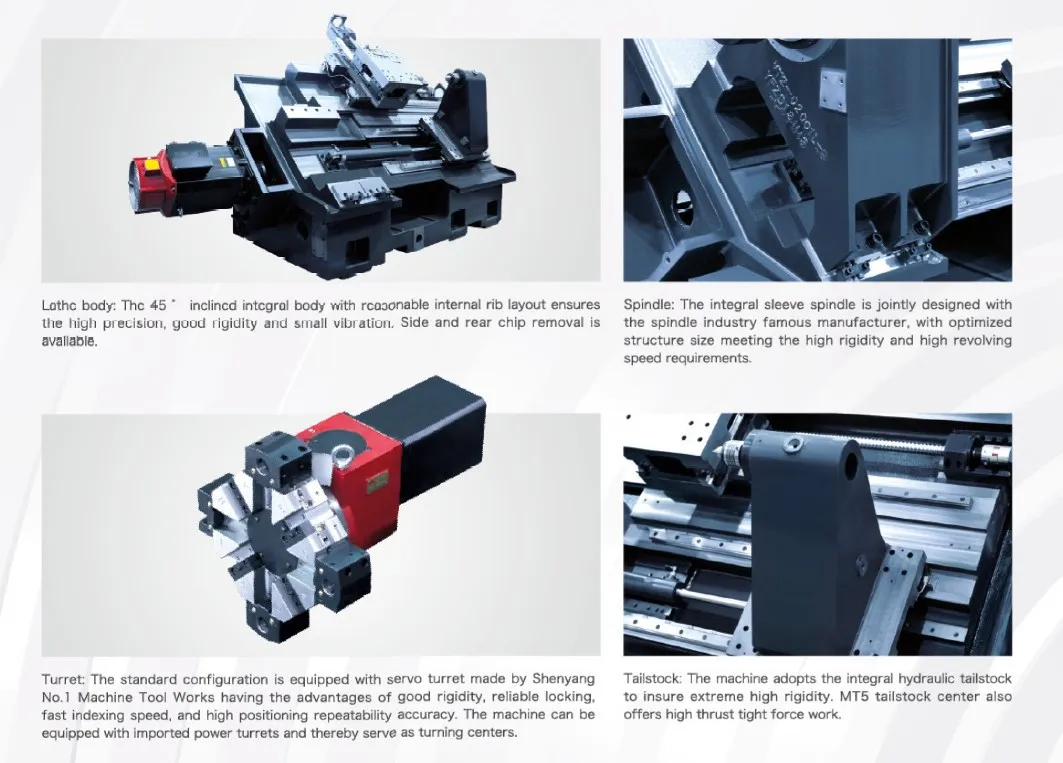

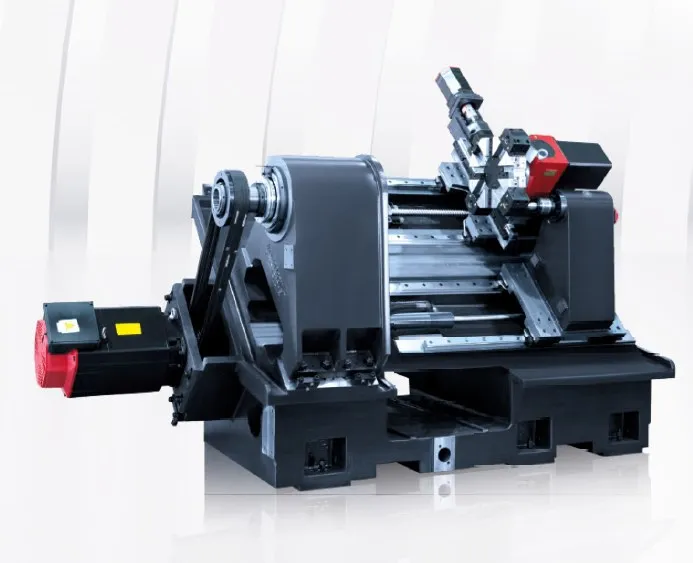

Lathe body: The 45 • inclined integral body with a reasonable internal rib layout ensures high precision, rigidity, and small vibration. Side and rear chip removal is available.

Spindle: The integral sleeve spindle is」ointly designed with the spindle industry’s famous manufacturer, with optimized structure size meeting the high rigidity and revolving speed requirements.

Turret: The standard configuration is equipped with a servo turret made by Shenyang No. l Machine Tool Works has the advantages of good rigidity, reliable locking, fast indexing speed, and high positioning repeatability accuracy. The machine can be equipped with imported power tl—lrrets and寸ereby serve as turning centers.

Tailstock: The machine adopts the integral hydraulic tailstock to ensure extremely high rigidity. MT5 tailstock center also offers high thrust tight force work.

Feed System: Ball screw and ball linear guideway with premium quality promotes machining accuracy and rapid traverse. It allows users to improve machining precision and production efficiency.

Chip Removal System: There are three types of chip removal modes available for selection: left chip removal, proper chip removal, and rear chip removal. The cooling pump is a large flow high head. The coolant tank and chip conveyor are separated from the main machine to ensure that the device’s accuracy shall not be affected by cutting heat.

Tool Measuring Device(option): The tool setting device could measure the coordinate of the tool profile top automatically so that the user can take less time to measure the tool. Tool abrasion will be compensated automatically.

Receiver/Feeder(option): With the production rhythm, receivers send the workpiece to the machining position. Then, it picks up a box, spins to the position to get the workpiece, and puts it into the collection box. Users can get the workpieces without stopping the machine.

The overall structure of this machine is perfected with the finite element method. With the most reasonable and compact structure, it has the best rigidity.

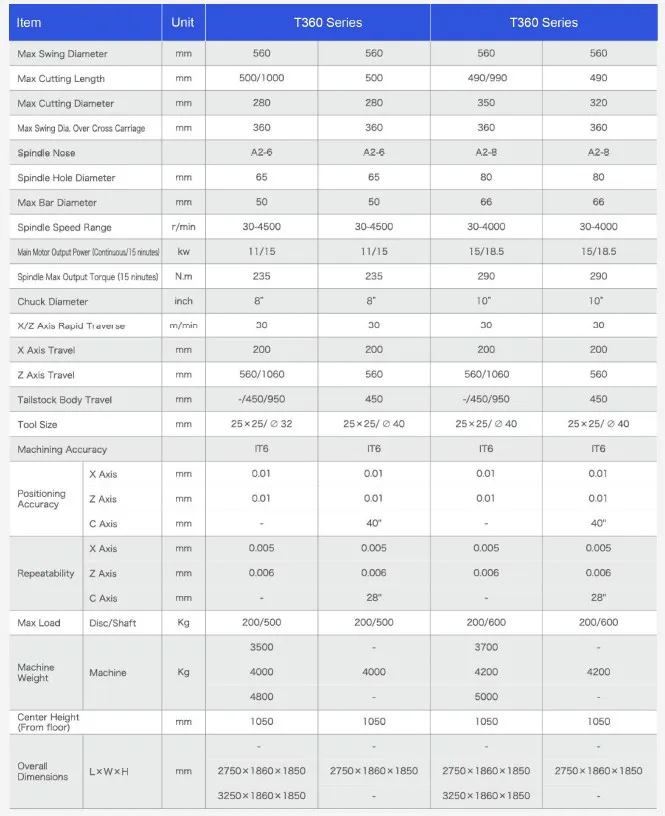

Product Parameter:

Main Specification:

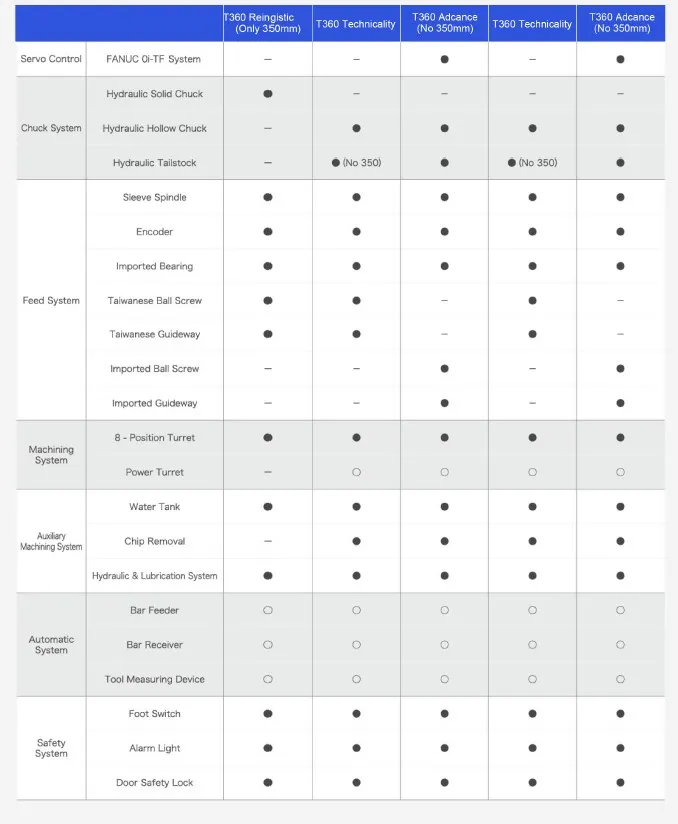

Standard & Option:

Our Company:

We are the industry’s leading CNC machine tools and intelligent equipment manufacturing and industrial service providers, with a perfect casting production line, intelligent machine tool assembly line, intelligent testing equipment, and equipped with professional R & D, manufacturing, sales team, aiming to provide high-quality CNC machine tools and intelligent equipment solutions for the industry.

Relying on strong CNC machine tool research and development and manufacturing strength, we provide customers with high-quality machine tool equipment while integrating and optimizing the industrial chain, and provide customers with shared machine tools, intelligent tool cabinets, automation integrated solutions, tool health monitoring system and other whole industry chain equipment and life cycle industrial services. A full range of enterprises to enable high-quality products, professional services to achieve industry leaders.

We have DISA vertical line, horizontal line, resin sand line lost mold production line and continuous casting production line and other industry leading casting production line, can achieve an annual output of 300,000 tons of casting capacity, and has a complete manufacturing system from casting and forging gold, machine orange processing, hot table processing, packaging and final assembly to warehousing and distribution.

Our assembly manufacturing base has advanced lathe flow assembly line standard vertical assembly line, medium and large equipment assembly line equipped with coordinate inspection and precision inspection. The constant temperature laboratory is equipped with high-end inspection equipment such as Weil Profiler and Renishaw Laser Interferometer from Zeiss high-performance coordinate measuring machines, providing the industry with high-quality CNC machine tools and integrated automation solutions.