Description

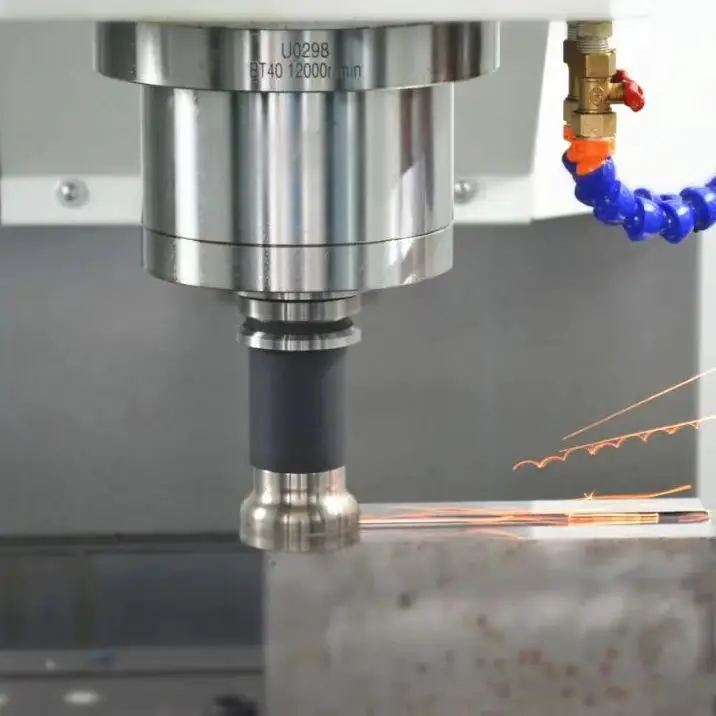

Experience precision and power like never before with our brand new, state-of-the-art DMTG CNC Lathe. This vertical machining center is designed with a slant bed and live tools for advanced operations. Manufactured with a BT40 spindle taper, it allows for single spindle operations, making it a perfect addition to any manufacturing plant, retail shop, or construction work site.

Product Features

Our DMTG CNC Lathe is engineered for heavy-duty work and boasts numerous features that set it apart. These include:

- High Precision: With a positioning accuracy of ±0.008mm and repeatability of 0.005mm, rest assured that this machine will consistently produce intricate and accurate workpieces.

- Multi-Axis Capabilities: It comes with optional 3, 4, or 5 axes for versatile machining operations.

- High Performance Spindle: The spindle motor power of 7.5/11kw and a maximum speed of 12,000rpm ensures optimal machining performance.

- Seamless Tool Change: The machine is equipped with a tool magazine capacity of 24, facilitating a swift tool change within 2 seconds.

- Versatile CNC Control System: Choose from GSK, FANUC, MITSUBISHI, KND, or Siemens, depending on your preference and requirements.

At our company, we have the capabilities and expertise to produce this exceptional product. We make use of advanced casting production lines, intelligent machine tool assembly lines, and state-of-the-art testing equipment to ensure optimal quality and performance.

Product Usage

Our DMTG CNC Lathe is designed to cater to a plethora of industries such as building material shops, machinery repair shops, manufacturing plants, retails, and construction work. Each feature of this machine has been specifically engineered to aid in delivering the best results.

Maintenance and Care

Maintaining and caring for your DMTG CNC Lathe ensures its longevity and optimal performance. This includes:

- Regular Inspections: Regularly check the condition of the machine, looking out for any signs of wear or damage.

- Proper Cleaning: Keep the machine clean, removing any dust, dirt, or debris that may interfere with its operation.

- Lubrication: Regularly lubricate moving parts to ensure smooth and efficient operation.

- Regular Replacement: Replace worn-out parts as necessary to maintain operational efficiency.

Product Selection

Choosing between a CNC machine and a conventional manually operated machine largely depends on your needs. CNC machines offer numerous advantages such as precision, automation, and versatility, making them an ideal choice for complex and high-volume manufacturing processes.

Act Now to Enhance Your Manufacturing Capabilities

Don’t miss out on the chance to take your manufacturing capabilities to the next level. Our DMTG CNC Lathe is designed to provide you with unparalleled versatility, precision, and efficiency. Contact us today to explore the product and make your purchase.

As the industry’s leading CNC machine tools and intelligent equipment manufacturer and service provider, we are committed to providing high-quality CNC machine tools and intelligent equipment solutions. Our professional R&D, manufacturing, and sales teams are ready to assist you with all your needs.