Description

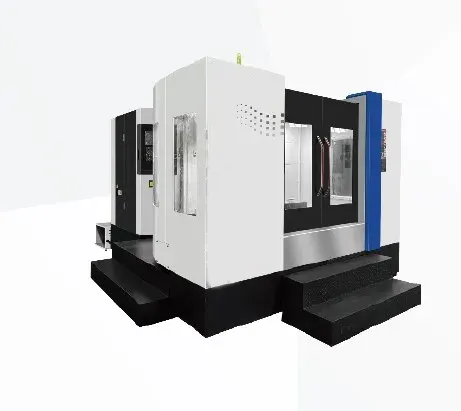

U Series Five-Axis Vertical Machining Center

The U Series Five-Axis Vertical Machining Center represents the pinnacle of precision and versatility in the world of machining. With its advanced features, exceptional accuracy, and extensive capabilities, this machining center empowers industries to achieve complex machining tasks with utmost efficiency and superior results.

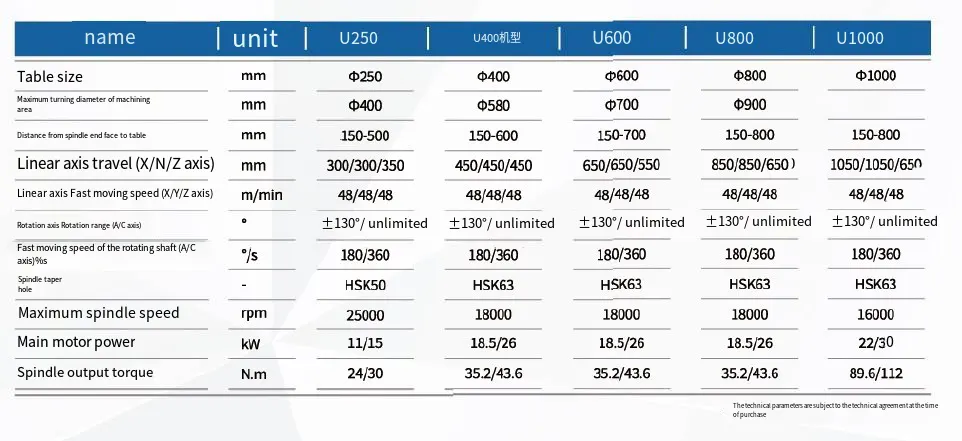

Product Parameter:

Five axis linkage high speed and precision

Can realize any position positioning processing

Machine tool performance optimization

Unparalleled Precision:

The U Series Five-Axis Vertical Machining Center is engineered to deliver unparalleled precision, ensuring the highest quality output for a wide range of machining applications. Let’s delve into its key characteristics:

- Rigidity and Stability:

- The machining center features a robust and rigid structure, constructed using high-quality materials.

- This structural integrity minimizes vibrations, enhances stability, and improves machining accuracy.

- High-Precision Spindle:

- The U Series boasts a high-precision spindle that ensures accurate rotational movement.

- With minimal run-out and excellent concentricity, it enables precise machining and superior surface finishes.

- Advanced Control Systems:

- This machining center incorporates sophisticated control systems that ensure precise movement of the five axes.

- The seamless coordination of these axes allows for complex machining operations while maintaining exceptional accuracy.

Enhanced Versatility:

The U Series Five-Axis Vertical Machining Center offers unmatched versatility, enabling manufacturers to tackle a wide range of machining tasks with ease. Here are some key features that enhance versatility:

- Five-Axis Machining:

- The machining center enables five-axis simultaneous machining, providing unparalleled flexibility to produce complex geometries.

- This capability eliminates the need for multiple setups, reducing production time and enhancing efficiency.

- Swivel Rotary Table:

- The U Series is equipped with a swivel rotary table that facilitates precise positioning of the workpiece.

- This feature enables the machining of parts from various angles, expanding the range of possible machining operations.

- Tool Magazine and Changer:

- The machining center includes a tool magazine and changer that streamline tool selection and changes.

- With a wide range of tooling options readily available, it allows for efficient and uninterrupted machining.

Our Company:

We are the industry’s leading CNC machine tools and intelligent equipment manufacturing and industrial service providers, with a perfect casting production line, intelligent machine tool assembly line, intelligent testing equipment, and equipped with professional R & D, manufacturing, sales team, aiming to provide high-quality CNC machine tools and smart equipment solutions for the industry.

Relying on strong CNC machine tool research and development and manufacturing strength, we provide customers with high-quality machine tool equipment while integrating and optimizing the industrial chain, and provide customers with shared machine tools, intelligent tool cabinets, automation integrated solutions, tool health monitoring system and other whole industry chain equipment and life cycle industrial services. A full range of enterprises to enable high-quality products and professional services to achieve industry leaders.

We have a DISA vertical line, horizontal line, resin sand line lost mold production line, continuous casting production line, and other industry-leading casting production lines; we can achieve an annual output of 300,000 tons of casting capacity and have a complete manufacturing system from casting and forging gold, machine orange processing, hot table processing, packaging, and final assembly to warehousing and distribution.

Our assembly manufacturing base has an advanced lathe flow assembly line, standard vertical assembly line, and medium and large equipment assembly line equipped with coordinated and precise inspection. The constant temperature laboratory has high-end inspection equipment such as Weil Profiler and Renishaw Laser Interferometer from Zeiss high-performance coordinate measuring machines, providing the industry with high-quality CNC machine tools and integrated automation solutions.