Description

V Series Vertical CNC Machine Tools

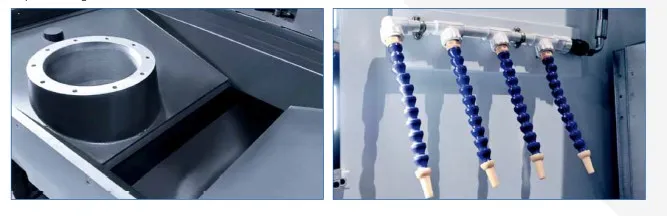

Integral external protection

The integral protection structure ensures waterproof performance.

Convenient internal sliding door

Lower work intensity and better protection performance.

Maximum cutting diameter:600mm

Maximum spindle speed:2000r/min

Two-axis rapid traverse speed:20m/min

Application Fields:

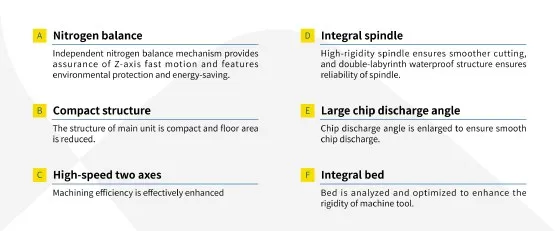

Structural Features:

Product Introduction:

V4 Series CNC Vertical Lathe:

The product features a compact and robust high-rigidity structure. It applies to the machining of automotive components such as small-size brake discs and flywheels, as well as electric motors and water pump housing. The product can be used for soft/hard turning of small size bearings and is able to realize the replacement of grinding by turning

V5 Series CNC Vertical Lathe:

The product features the perfect combination of high machining performance and low floor area occupation and applies to the machining of automotive components such as wheel hubs, brake discs flywheels, etc. The product can also be used for soft/hard turning of bearings and can realize the replacement of grinding by turning. The product is able to realize the turning of the brake disc after the installation of an auxiliary shaft, substantially enhancing efficiency and machining accuracy.

V8 Series CNC Vertical Lathe:

Box structures featuring excellent shock-absorbing performance and larger machining space are suitable for machining automotive components such as brake hubs, wheel hubs and reducer housing, elevator wheels, engineering chain wheels, valves, motor housing, etc. The product can also be used for soft/complex machining of bearings and can realize the replacement of grinding by turning. The machine tool is convenient for installing various unique fixtures and can be used for machining components of complicated housings and components of abnormal shapes.

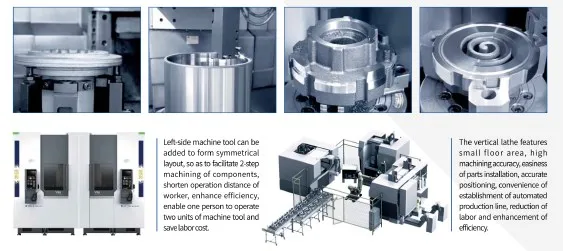

The left-side machine tools can be added to form a symmetrical layout so as to facilitate the 2-step machining of components, shorten the operation distance of workers, enhance efficiency, enable one person to operate two units of machine tools, and save labor costs.

The vertical lathe features a small floor area, high machining accuracy, easiness of parts installation, accurate positioning, the convenience of the establishment of the automated production line, reduction of labor, and enhancement of efficiency.

♦ The integrated spindle meets the requirements on high rigidity, high rotation speed and high accuracy of machine tool.

♦ The fit clearance with bed is reduced to 0.02mm and the shock absorption effect is good.

♦ Foreign matter penetration proof device ensures that spindle is able to work accurately under severe machining environment.

♦ Replacement in lieu of repair

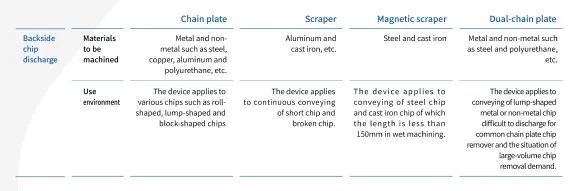

Various chip conveying devices:

The nitrogen balance system reduces

the motion impact of the z-axis to the minimum

In comparison with the previous hydraulic balance system, the nitrogen balance system features the following advantages:

♦ It does not need external power equipment and saves energy.

♦ It is able to adapt to high-speed rotation and lift/lower quickly and stably, is free from noise, and improves the disadvantages of balance weight and hydraulic system.

♦ In the machining process, it is able to enhance accuracy and degree of finish substantially, reduce slight shock and extend the useful life of lead screw and motor.

More optimal local structure

The product provides different machining performances, cutter head modes, and cutter layouts to improve the cutting effect.

Large chip discharge outlet and concentrated treatment of iron chip and cutting fluid

Separated waterfall chip flushing structure

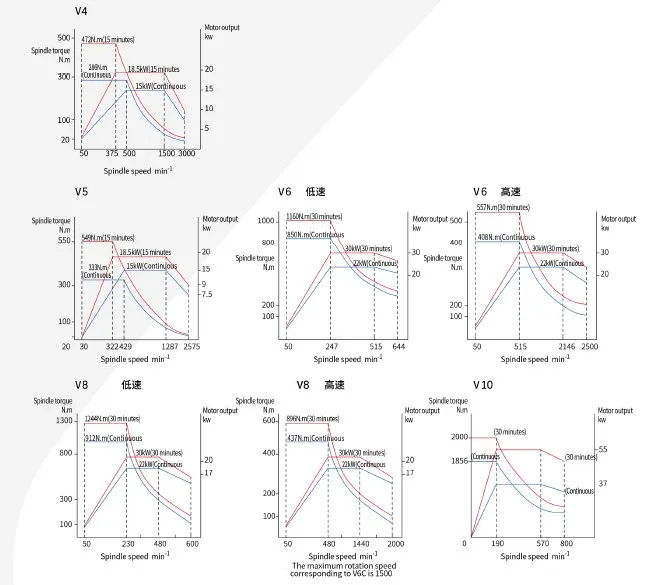

Power/torque Diagram:

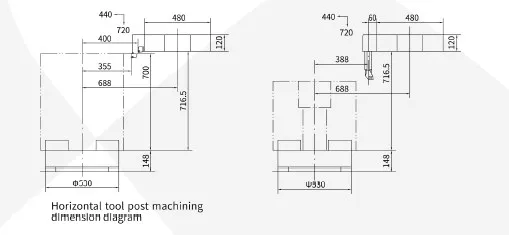

V8 Machining Travel Diagram:

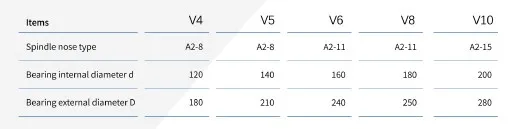

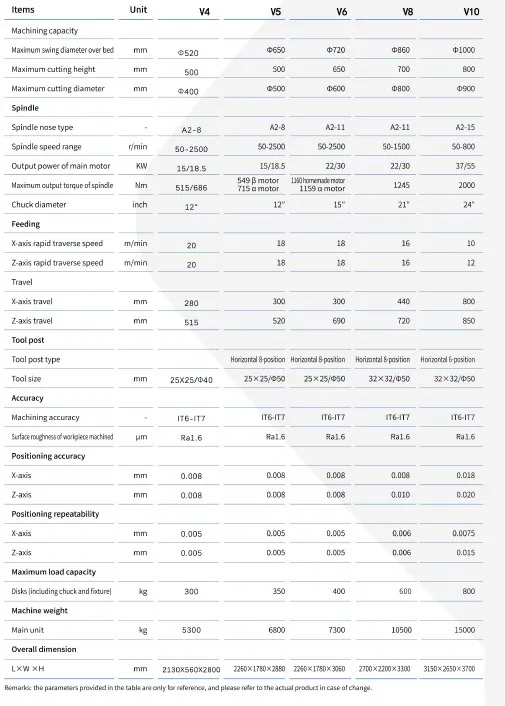

Techinical Parameter:

Configuration of the Machine:

\

\

Our Company:

We are the industry’s leading CNC machine tools and intelligent equipment manufacturing and industrial service providers, with a perfect casting production line, intelligent machine tool assembly line, intelligent testing equipment, and equipped with professional R & D, manufacturing, sales team, aiming to provide high-quality CNC machine tools and intelligent equipment solutions for the industry.

Relying on strong CNC machine tool research and development and manufacturing strength, we provide customers with high-quality machine tool equipment while integrating and optimizing the industrial chain, and provide customers with shared machine tools, intelligent tool cabinets, automation integrated solutions, tool health monitoring system and other whole industry chain equipment and life cycle industrial services. A full range of enterprises to enable high-quality products, professional services to achieve industry leaders.

We have DISA vertical line, horizontal line, resin sand line lost mold production line and continuous casting production line and other industry leading casting production line, can achieve an annual output of 300,000 tons of casting capacity, and has a complete manufacturing system from casting and forging gold, machine orange processing, hot table processing, packaging and final assembly to warehousing and distribution.

Our assembly manufacturing base has advanced lathe flow assembly line standard vertical assembly line, medium and large equipment assembly line equipped with coordinate inspection and precision inspection. The constant temperature laboratory is equipped with high-end inspection equipment such as Weil Profiler and Renishaw Laser Interferometer from Zeiss high-performance coordinate measuring machines, providing the industry with high-quality CNC machine tools and integrated automation solutions.