Description

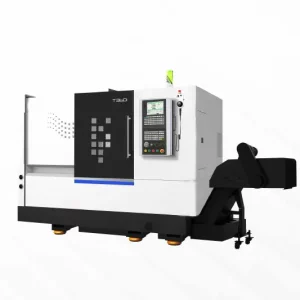

Introducing the cutting-edge DMTG 3 Axis 4 Axis 5 Axis Machine Center, a high precision, CNC vertical machining center with a linear guide rail. This machine is new and features a BT40 spindle taper. It is equipped with a single spindle and has a dimension of 2496*2530*2679. The machine weighs 7 tons and has a table size of 1000*560mm.

Product Features

The DMTG 3 Axis 4 Axis 5 Axis Machine Center is designed with state-of-the-art features that enhance its performance and versatility. These include:

- CNC Control System: The machine boasts a CNC control system from leading brands such as GSK, FANUC, MITSUBISHI, KND, and Siemens, ensuring exceptional control and precision.

- High Precision: With a positioning accuracy of ±0.008mm and repeatability of 0.005mm, the product guarantees high precision machining.

- Speed and Power: The machine has a spindle speed range of 0 – 12000 r.p.m, powered by a 7.5/11Kw spindle motor.

- Tool Magazine Capacity: The machine comes with a 24 tool magazine capacity, allowing for a variety of operations without needing to frequently change tools.

- Multi-functionality: The machine is multifunctional, making it suitable for a range of industries including building material shops, machinery repair shops, manufacturing plants, retail, and construction works.

We are capable of producing this high-quality, multifunctional CNC machine, catering to your specific needs and specifications.

Product Usage

The DMTG 3 Axis 4 Axis 5 Axis Machine Center is an integral tool in various manufacturing processes. Here’s how it can be utilized:

- High Precision Machining: The machine’s high precision capabilities make it perfect for tasks that demand exceptional accuracy and repeatability.

- Versatile Operations: With its multi-axis and high tool magazine capacity, the machine can perform a variety of operations, reducing the need for multiple machines.

- Speed and Efficiency: The machine’s high spindle speed and power, coupled with its rapid feed speed, make it a highly efficient tool in any manufacturing line.

- CNC Control: The CNC control system allows for superior control and precise machining, making it easier to achieve complex designs and patterns.

- Multi-industry Application: The machine’s multifunctionality makes it suitable for various industries, enhancing productivity and efficiency.

Product Maintenance

To ensure the longevity and optimum performance of the DMTG 3 Axis 4 Axis 5 Axis Machine Center, regular maintenance is essential. This includes:

- Regular Inspection and Repair: Regular inspections can help identify any issues early, preventing potential damage.

- Cleaning: Regular cleaning is crucial to keep the machine free from dust and debris that can affect its performance.

- Lubrication: Regular lubrication helps ensure the machine parts run smoothly, reducing wear and tear.

- Part Replacement: Regular replacement of worn-out parts can prevent machine breakdowns and enhance performance.

Product Selection

When choosing between a CNC machine and a conventional manually operated machine, it’s important to consider the benefits of CNC machines. These include high precision, versatility, speed, and efficiency. CNC machines also require less manual labor, reducing the risk of human error and enhancing productivity.

Take Action Now

Explore the unmatched precision and efficiency of the DMTG 3 Axis 4 Axis 5 Axis Machine Center. Enhance your manufacturing processes with this high-quality, versatile machine. Contact us now to learn more and make your purchase.

About Us

We are the industry’s leading CNC machine tools and intelligent equipment manufacturing and industrial service providers. We have a perfect casting production line, an intelligent machine tool assembly line, intelligent testing equipment, and a professional R & D, manufacturing, sales team. Our aim is to provide high-quality CNC machine tools and intelligent equipment solutions for the industry.