Description

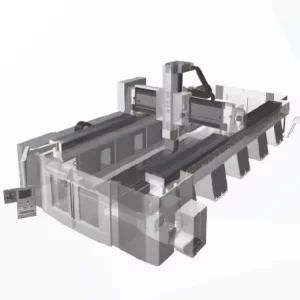

The DMTG High Speed Low Cost 3 axis 4 axis 5 Axis CNC Vertical Machining Center VMC850 Automatic Milling CNC Machine Center is a new, multifunctional machine with a single spindle. Its key specifications include a spindle taper of BT40, a weight of 7 tons, and a table size of 1000*560mm. It is equipped with a CNC Control System that can be customized to GSK, FANUC, MITSUBISHI, KND, or Siemens. The machine has a positioning accuracy of ±0.008mm and a repeatability of 0.005mm.

Product Highlights

This state-of-the-art CNC machine center is designed with several distinguishing features that set it apart.

- High Speed: It operates at a range of spindle speed from 0 to 12000 r.p.m, ensuring rapid machining.

- Multifunctional: With 3, 4, or 5 axes, it can handle complex machining tasks with ease.

- Precision: Offering positioning accuracy of ±0.008mm and repeatability of 0.005mm, it delivers exceptional precision.

- Control System: The CNC Control System can be customized to user preference, with options including GSK, FANUC, MITSUBISHI, KND, or Siemens.

- Warranty: A one-year warranty is provided, guaranteeing the quality of our product.

We are proud of our capability to produce such innovative products that lead the industry.

Product Usage

This CNC machine center is designed for diverse applications and can be used in various industries such as building material shops, machinery repair shops, manufacturing plants, retail, and construction works. It is particularly beneficial in situations where high precision and multifunctional machining are required. The optional CNC control systems add versatility to this machine, making it adaptable to different operational needs. Regular inspection and repairs, cleaning, lubrication, and timely replacement of worn-out parts will ensure the machine’s optimal performance and longevity.

Product Selection

When choosing between a CNC machine and a conventional manually operated machine, it’s important to consider the advantages of CNC machines. CNC machines offer high precision, flexibility, and automation. They allow for complex machining tasks, reduce human error, and can operate continuously, increasing productivity and efficiency greatly.

Maintenance Tips

To maintain the CNC machine center in top condition, regular inspection and repairs are necessary to identify and rectify any technical issues promptly. Regular cleaning is also crucial to remove any dust or debris that could impact the machine’s performance. Lubrication of moving parts will ensure smooth operation and minimize wear and tear. Lastly, regular replacement of worn-out parts will prevent machine breakdowns and prolong the machine’s lifespan.

Explore our CNC Machine Center Today

Transform your manufacturing processes with our DMTG High Speed Low Cost 3 axis 4 axis 5 Axis CNC Vertical Machining Center VMC850 Automatic Milling CNC Machine Center. We invite you to explore this product and discover how its innovative features can revolutionize your operations. Our expert team is on standby to assist you with any inquiries, provide a comprehensive quote, and guide you through the purchase process. Take this step towards enhanced precision, efficiency, and productivity in your manufacturing processes.

About Us

We are the industry’s leading CNC machine tools and intelligent equipment manufacturing and industrial service providers. Our state-of-the-art facilities include a perfect casting production line, intelligent machine tool assembly line, intelligent testing equipment, and a professional R & D, manufacturing, sales team. Our mission is to provide high-quality CNC machine tools and intelligent equipment solutions for the industry.