Description

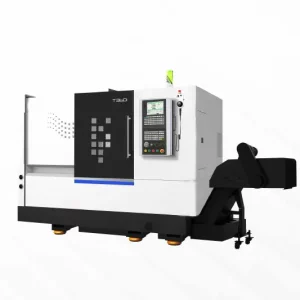

The CNC Turning Center is a vertical machining center that boasts exceptional performance. This new model is rapidly delivered and comes with a wide array of features that make it perfect for a range of industries.

Product Features

Our Vertical Machining Center is designed with precision and efficiency in mind. Here are some of the key features that make it stand out:

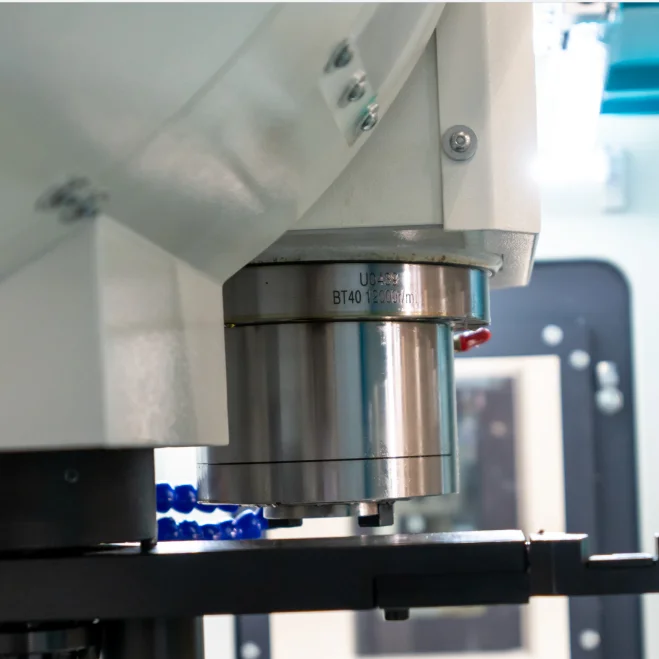

- High Accuracy: With positioning accuracy and repeatability of ±0.002mm, our product offers high precision machining.

- Quick Tool Change: The minimum tool change time is only 1 second, ensuring high efficiency in operations.

- Spindle Power: The spindle motor power ranges from 7.5 to 15 kW, offering versatility for different machining requirements.

- Control System: The CNC system can be controlled using GSK, FANUC, or Siemens, providing flexibility for your operations.

- Wide Application: Suitable for various industries such as garment shops, building material shops, manufacturing plants, and food & beverage factories.

With our dedicated team of professionals, we can produce this high-performance Vertical Machining Center that will meet all your industry needs.

Product Usage

Our Vertical Machining Center is designed to be highly user-friendly and efficient. Here is how you can use our product:

- The CNC system allows for precise control over the machining process, ensuring high-quality results.

- The quick tool change feature makes it easy to switch between different operations, increasing your productivity.

- The high-powered spindle motor can handle a wide variety of materials, making our machine versatile for different industries.

- The wide application scope means it can be used in various sectors for making everything from clothing to food and beverage products.

Maintenance

To ensure the longevity and optimal performance of our Vertical Machining Center, we recommend the following maintenance methods:

- Regular Inspection and Repair: Regularly inspect the machine for any wear or damage and carry out necessary repairs.

- Cleaning: Keep the machine clean to prevent any dust or debris from affecting its performance.

- Lubrication: Regularly lubricate the moving parts to reduce friction and wear.

- Replacement: Replace any worn-out parts as necessary to maintain optimal performance.

Product Selection

Choosing between a CNC machine and a conventional manually operated machine depends on your specific needs. CNC machines offer several advantages over manual machines, such as increased efficiency, precision, flexibility, and safety. If these benefits align with your requirements, a CNC machine like our Vertical Machining Center is the ideal choice.

Call to Action

Don’t miss out on the opportunity to streamline your operations with our Vertical Machining Center. Its high precision, quick tool change feature, powerful spindle motor, and wide application scope make it the perfect addition to your industry. Contact us today to explore our product and make your purchase!

About Our Company

We are the industry’s leading CNC machine tools and intelligent equipment manufacturing and industrial service providers. We offer a perfect casting production line, intelligent machine tool assembly line, intelligent testing equipment, and a professional R & D, manufacturing, and sales team. Our aim is to provide high-quality CNC machine tools and intelligent equipment solutions for the industry.