Description

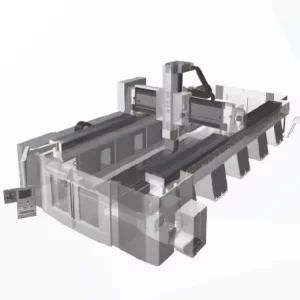

Best Sale MDH CNC Horizontal Machining Center HMC Heavy Duty CNC Milling Machine Center For Metal

Our top-of-the-range MDH CNC Horizontal Machining Center is designed for heavy-duty metal milling tasks. This brand-new machinery boasts a BT50 spindle taper, a single spindle and a 3 or 4 axis CNC control system from FANUC or Siemens. Its total dimensions are 6153*3717*3827mm, weighs 24 tons, and has a table size of 800*800mm. The machine offers superior positioning accuracy of 0.01mm and repeatability of 0.006mm. The spindle motor power is a formidable 25kW, and the table can support loads of up to 2000kg. The tool magazine capacity is 40, with a minimum tool change time of 2 seconds.

Product Highlights

The Dalian MDH CNC Horizontal Machining Center stands out in the market for several reasons:

- It offers a high level of precision in metal processing.

- It is multifunctional, providing a wide range of machining capabilities.

- The machine is equipped with either a FANUC or Siemens control system, ensuring reliable and smooth operation.

- The machine is designed for heavy-duty use, with a maximum table load of 2000kg.

- It provides a rapid feed speed of up to 45m/minute, increasing productivity.

As a leading provider of CNC machine tools, we manufacture this product to meet the highest industry standards.

Product Usage

The Dalian MDH CNC Horizontal Machining Center is designed for a variety of applications:

- Metal Processing: This machine is ideal for a wide range of metal processing tasks, thanks to its high precision and multifunctional capabilities.

- CNC Machining: The machine’s CNC control system offers an automated, accurate, and efficient machining process.

- Heavy-Duty Milling: With its sturdy build and powerful motor, the machine is perfect for heavy-duty milling tasks.

Maintenance

To ensure optimal performance and longevity of the Dalian MDH CNC Horizontal Machining Center, there are several maintenance steps to follow:

- Regular Inspection and Repair: Check the machine regularly for any signs of wear and tear or damage and promptly conduct necessary repairs.

- Regular Cleaning: Keep the machine clean to prevent build-up of dirt and grime that could affect its performance.

- Lubrication: Regularly lubricate moving parts to reduce friction and prevent overheating.

- Regular Replacement: Replace worn-out parts promptly to maintain machine efficiency and prevent damage to other components.

Product Selection

Unlike conventional manually operated machines, a CNC machine offers higher precision, efficiency, and productivity. The primary advantages of using CNC machines in manufacturing processes include automated operation, lower labor costs, consistent product quality, and greater safety.

Call to Action

Explore the superior precision, functionality, and durability of our Dalian MDH CNC Horizontal Machining Center. Take your metal processing tasks to the next level with this high-quality, heavy-duty machine. Contact us today to learn more about this product or to place your order.

About Us

We are the industry’s leading CNC machine tools and intelligent equipment manufacturing and industrial service providers. We have a perfect casting production line, intelligent machine tool assembly line, intelligent testing equipment, and a professional R & D, manufacturing, sales team. Our goal is to provide high-quality CNC machine tools and intelligent equipment solutions for the industry.