Description

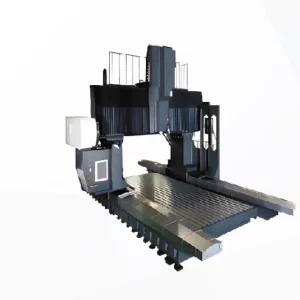

Introducing our top-of-the-line, brand new Horizontal CNC Milling Machine, specifically the Auto Tool Changer MDH Series. This state-of-the-art machine is packed with the best features and technology, including a BT50 Spindle Taper, single spindle, and a FANUC or Siemens CNC Control System. With dimensions of 6153*3717*3827, it’s a sizeable machine that can handle the heavy-duty manufacturing tasks you need done.

Product Features and Benefits

The Auto Tool Changer MDH Series is a game-changer in the world of CNC Machine Tools. It’s designed with the following key features:

- Easy to operate: It doesn’t matter if you’re a novice or a seasoned professional; this machine is user-friendly and easy to navigate.

- Highly precise: With a positioning accuracy of 0.01mm and a repeatability of 0.006mm, you can trust this machine for highly accurate machining tasks.

- Versatile: It’s not just a milling machine; it also excels in drilling and threading operations.

- Durable: With its core components being bearings, this machine is built to last.

- Comprehensive warranty: The machine and its core components come with a 1-year warranty.

We have the capability and infrastructure to produce this unparalleled machine tool. Our commitment to quality and efficiency reflects in every single unit we manufacture.

Using the Auto Tool Changer MDH Series

The Auto Tool Changer MDH Series is designed to make machining tasks effortless and efficient. It’s perfect for various industries including building material shops, manufacturing plants, retail, construction works, and energy & mining. The machine’s control system allows for easy programming and operation while its high precision ensures the production of high-quality parts.

Maintenance of the Machine

To ensure longevity and optimal performance, regular maintenance is essential. This includes:

- Regular inspection and repairs: Regularly check the machine for any wear and tear and conduct necessary repairs.

- Cleaning: Regular cleaning helps in maintaining the machine’s performance and preventing any potential damage caused by the accumulation of dirt or debris.

- Lubrication: Regularly lubricating the moving parts helps in reducing friction and enhancing the machine’s lifespan.

- Regular replacement of parts: Regular replacement of worn-out parts ensures the machine is always at its best performance.

Choosing the Perfect CNC Machine

Compared to conventional manually operated machines, CNC machines offer precision, repeatability, and the ability to produce complex parts. The Auto Tool Changer MDH Series is a prime example of this, offering unparalleled machining capabilities and significant advantages in manufacturing processes.

Take the Next Step

Upgrade your manufacturing capabilities with the Auto Tool Changer MDH Series Machine today. Experience the difference in precision, efficiency, and reliability. Don’t just take our word for it; explore our product and see for yourself. Contact us now to learn more or to make a purchase.

About Us

We are the industry’s leading CNC machine tools and intelligent equipment manufacturing and industrial service providers. We boast a perfect casting production line, intelligent machine tool assembly line, intelligent testing equipment, and are equipped with a professional R&D, manufacturing, and sales team. Our aim is to provide high-quality CNC machine tools and intelligent equipment solutions for the industry.