Description

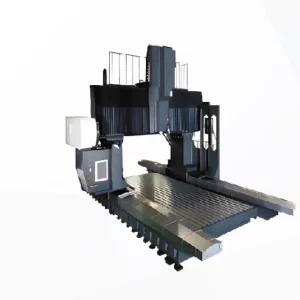

Introducing our top-selling, high-speed, large horizontal CNC Milling Machine MDH65. This state-of-the-art machining center utilizes an advanced FANUC control system to deliver superior performance and precision. The machine boasts a single spindle with a BT50 taper, a table size of 800*800 mm, and comes with a standard warranty of 1 year.

Product Highlights

This impeccable machining center comes with numerous appealing features that make it an industry favorite. Firstly, it operates using a FANUC or Siemens CNC Control System, ensuring high precision and efficiency. Secondly, it offers a considerable range of spindle speeds, from 0 to 8000 r.p.m, catering to various machining requirements. Thirdly, the machine has a maximum table load capacity of 2000 kg, enabling it to handle heavy-duty tasks with ease. Fourthly, it comes with a tool magazine capacity of 40, promoting seamless workflow and productivity. Lastly, the machine is easy to operate, making it user-friendly for operators of different skill levels. We take pride in manufacturing this high-performance CNC milling machine, designed to meet the diverse needs of various industries.

Product Usage

The MDH65 Horizontal Machining Center is incredibly versatile. It can be used for drilling, milling, and threading operations. Its high precision machining capability makes it suitable for industries where accuracy is paramount, such as the manufacturing of precision parts. The machine’s robust build and high-performance features allow it to work on different materials, including metals, making it a valuable asset in manufacturing plants, retail, construction works, and mining operations.

Product Maintenance

To ensure that the MDH65 continues to operate at its optimum capacity, regular maintenance is crucial. This includes regular inspection and repair to identify any potential issues early on and rectify them promptly. Regular cleaning is necessary to remove any debris that might affect the machine’s performance. Proper lubrication of the machine parts will minimize friction and wear, thereby prolonging the machine’s lifespan. Lastly, it is advised to replace parts regularly to maintain the machine’s efficiency and precision.

Product Selection

When choosing a CNC machine, it’s vital to consider its benefits over a conventional manually operated machine. CNC machines offer high precision, efficiency, and versatility, making them ideal for various manufacturing processes. They also reduce the chances of human error and can work round the clock, increasing productivity.

Call to Action

Take your manufacturing processes to the next level with our MDH65 Horizontal Machining Center. Experience unparalleled precision, efficiency, and versatility in your operations. Don’t miss out on the opportunity to boost your productivity and profitability. Contact us today to place your order or for more information about this top-notch CNC machine.

About Us

We are the industry’s leading CNC machine tools and intelligent equipment manufacturing and industrial service providers. We pride ourselves on our perfect casting production line, intelligent machine tool assembly line, intelligent testing equipment, and professional R & D, manufacturing, sales team. Our goal is to provide high-quality CNC machine tools and intelligent equipment solutions for the industry.